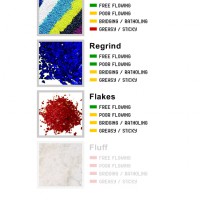

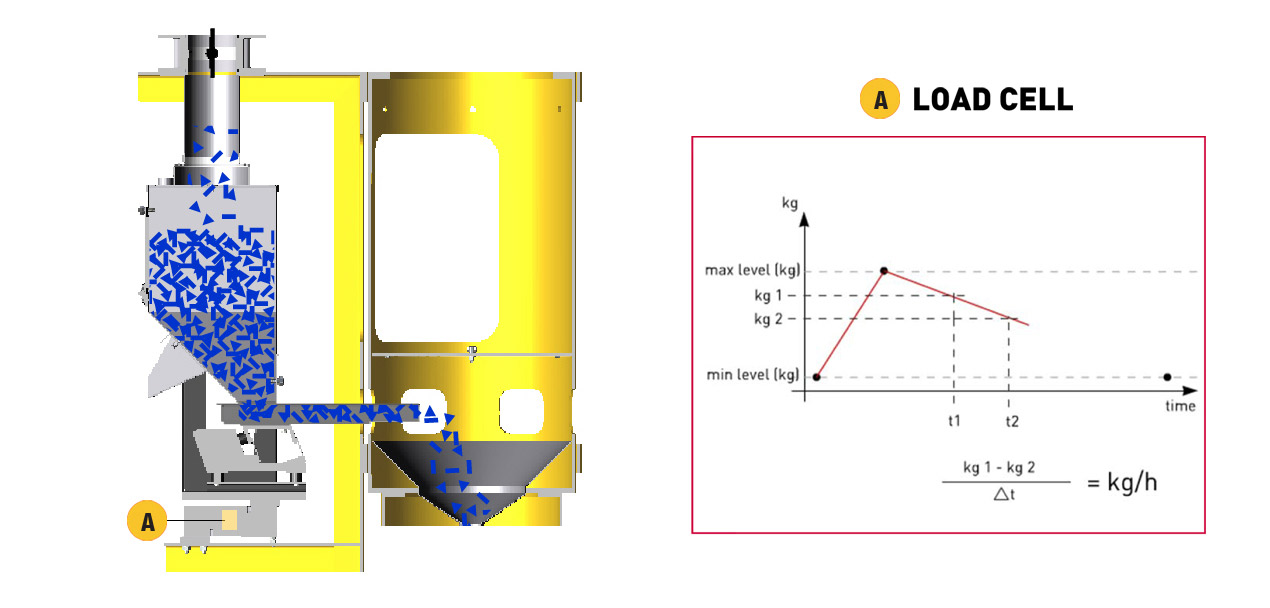

Continuous gravimetric blender, designed to blend pellets, regrind and flakes in extrusion processes where key-factors are the dosing accuracy, and the capability to follow and compensate the variations of unstable processes.

Gravifeed – Gravimentric loss-in-weight continuous blender for starve feed extruders

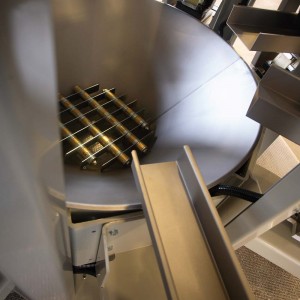

- Vibratory Tray Feeder.

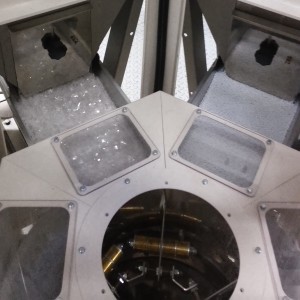

- Each ingredient (mains and additives) is continuously metered by individual vibratory tray feeders.

- Therefore the system is suitable to feed pellets and also regrind and flakes, with a wide variety of bulk densitiesì and flowability.

- Quick and easy access to all parts for maintenance cleaning.

- Clean out doors for fast removal of dust or ingredient residues and for visual inspection.

Extrusion control with starve feeding extruders

- Operator inputs the Melt Pressure Set‐Point (PSP) by the HMI

- Being the melt pump pressure directly related to the line total throughput (kg/h), Line Control system converts the PSP into a Troughput Set‐Point (TSP) and the TSP is sent, as an input, to the GRAVIFEED

- The Line Control system gets the melt Pressure Present‐Value (PPV) from the melt pump

- The Line Control system converts PPV) into the relevant Troughput Present‐Value (TPV)

- TPV is sent, as an input, to the GRAVIFEED

- The GRAVIFEED adjusts the throughput of each component:

– to keep the receipt

– to adjust TPV = TSP and keep therefore PPV= PSP

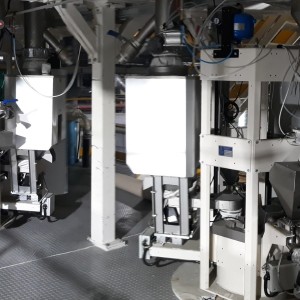

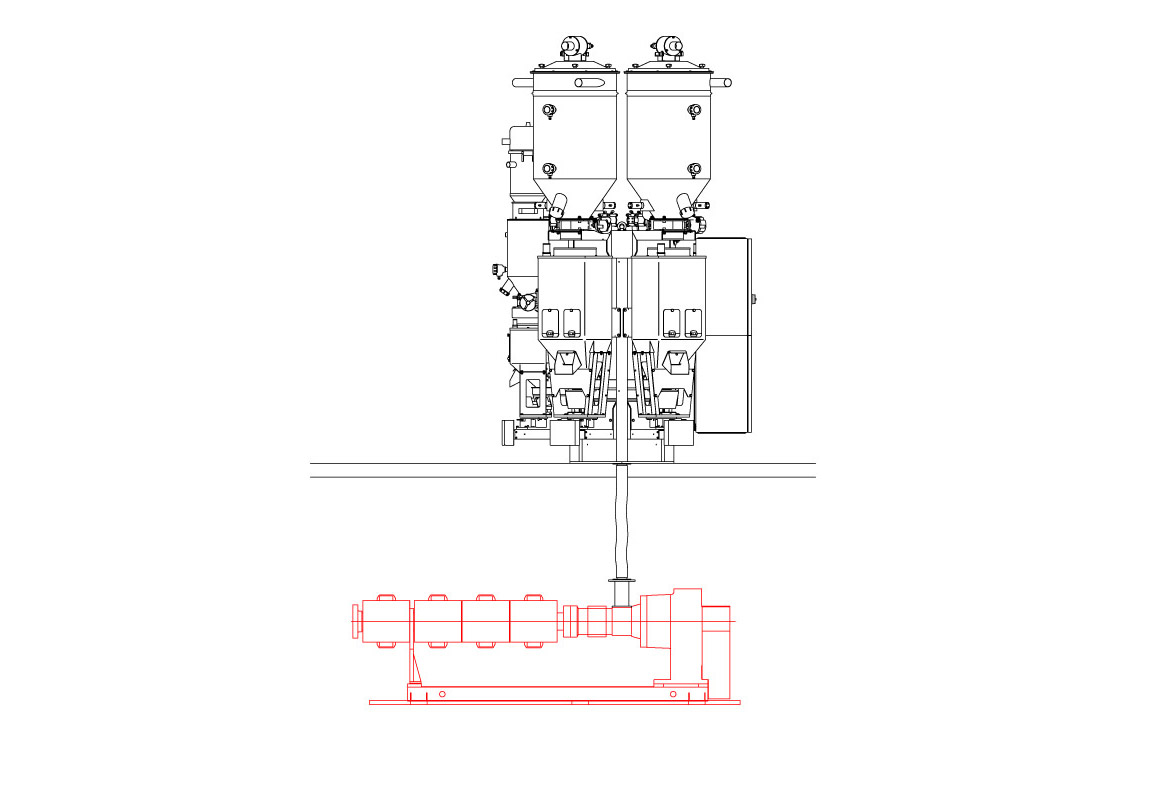

- On the throat of the processing machine

- On a mezzanine, to feed by gravity the supply hopper of the processing machine

- On a vacuum take-off stand, to feed one or more processing machineas blending station

WIDE RANGE OF NETWORKING OPTIONS FOR REMOTE CONTROL AND DATA ACQUISITION

- OPC via Ethernet (one entry-point)

- OPC via CanBus (one entry-point or multi entry-point)

- ModBus TCP/IP (one entry-point)

- RS485/422 ModBus (one entry-point or multi entry-point)

- Profibus (one entry-point or multi entry-point)

- CanBus (one entry-point or multi entry-point)

- Profinet (one entry-point)

- Ethernet I/P (one entry point)